main content:

The energy system of an electric vehicle is mainly composed of an energy management system, a power battery pack, and a charging system.

1. Energy management system

The main function of the energy management system is to distribute energy to each power mechanism of the electric vehicle and manage it later to improve the energy utilization rate of the electric vehicle. At the same time, it can also monitor the charging and discharging of the battery, monitor the change of its parameters, judge the state it is in, and prevent the occurrence of overcharge and overdischarge, so as to avoid damage to the battery pack and prolong its service life.

In order to avoid the damage to the battery caused by factors such as voltage imbalance between battery components during the driving process of electric vehicles, optimize the use of battery energy, and prolong the service cycle life of the battery, the indicators such as voltage, current and temperature indication of the battery must be monitored in real time. The energy management system of the battery is an electronic control unit with a microprocessor as the core, and its main function is to take various measures to monitor the parameters of the battery when it is in use. The monitored physical quantities include the following aspects:

①The voltage, current, external environmental factors and state of the battery;

②According to the data obtained by the sensor, the energy of the battery pack is obtained, and its SOC value is calculated;

③ Carry out charge and discharge control. According to the detected battery parameters, the system automatically controls the charge and discharge state of the battery to ensure the normal use of the battery and the stability and safety of its performance;

④The thermal management of the battery is carried out by collecting the data of the battery temperature measurement point in real time, and the temperature of the battery is controlled to prevent the occurrence of excessive temperature;

⑤ It can complete the data sorting and energy monitoring, and judge the usage of the battery according to the amount of energy;

⑥ It can realize the real-time tracking display of the working state of the battery, and complete the rapid update of the data.

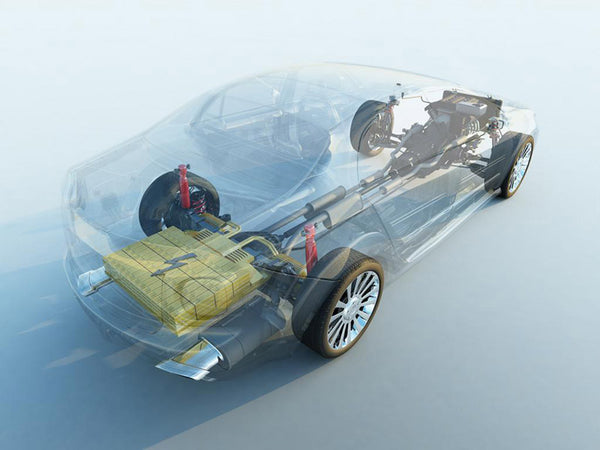

2. Power battery pack

The power battery pack not only provides electrical energy for the normal driving of electric vehicles, but also supplies energy for various auxiliary components and systems. The battery pack is mainly installed on the electric vehicle in series and parallel, so that its output voltage can meet the needs of driving the vehicle. At the same time, in order to improve the power generation efficiency of the battery, the similarity matching within a reasonable range is often carried out by comprehensively considering its performance requirements.

The energy system of an electric vehicle is an important guarantee for its driving range and a decisive factor. The main energy source of electric vehicles is the battery, so whether the battery is optimal will ultimately affect the economy of the entire vehicle. To this end, the battery of an electric vehicle should be able to meet the following three requirements:

①In terms of manufacturing, it is required to have the longest possible service life and control the cost within a low range;

②In terms of use, high energy and power density are required, fast charging and deep discharge, and good adaptability to the working environment (such as a wide ambient temperature range);

③ In terms of maintenance and recycling, it is required to be easy to maintain and have good recyclability, and the cost of recycling and maintenance should be considered.

The battery is the power source of the electric vehicle and the foundation of the energy system. Therefore, the pros and cons of its quality will greatly affect the performance of the electric vehicle and its mileage. At present, the more common and widely used power batteries on the market include lead-acid (Lead-Acid) batteries, nickel-metal hydride (Ni-MH) batteries and lithium-ion (Li-ion) batteries.

(1) Lead-acid battery. Due to the early development and application of lead-acid batteries, its production process has been quite mature, and the product quality is relatively high. In addition, lead is widely distributed and the price is relatively low, so it is more economical and practical. Therefore, it is widely used in the initial stage when the battery technology of electric vehicles is relatively immature, and it is the main power source of electric vehicles.

However, with the innovation of technology, the shortcomings of lead-acid batteries are becoming more and more obvious, mainly including the following aspects:

① The mass and volume of lead-acid batteries are large, which increases the total mass of electric vehicles, reduces the available space, and increases the energy consumption of vehicles;

②The utilization rate of lead-acid batteries is greatly affected by the outside world, and the efficiency under continuous operation is low;

③ Lead-acid batteries are limited by their own conditions after they are eliminated, and it is difficult to recycle them.

(2) Ni-MH battery. Nickel-metal hydride batteries have high specific energy, which can provide sufficient power for electric vehicles and can meet their power requirements in multiple operating conditions. In addition, since nickel-metal hydride batteries do not cause heavy pollution, green environmental protection is also a major advantage. In terms of use, the service life of nickel-metal hydride batteries is significantly higher than that of other batteries, and the charging and discharging performance is also relatively prominent, and the development prospects are great. Although nickel-metal hydride batteries are difficult to mass-produce at this stage due to their high cost, they will become the main power battery products developed in my country in the future due to their advantages in energy and service life. At present, nickel-metal hydride batteries have been used in some miniature cars in my country.

(3) Lithium-ion battery. Lithium-ion batteries not only have the advantages of large specific energy, light weight, high efficiency, and high power, but also have the advantages of long life, no pollution, and low requirements for the use environment and temperature range. The disadvantage is that the manufacturing cost is high, and it requires a higher investment in the development stage.

3. Electric vehicle charging system

The main function of the electric vehicle charging system is to convert the alternating current in the power grid into direct current through the process of rectification and power conversion and store it in the battery, so as to realize the charging of the electric vehicle. In order to achieve the required driving performance, electric vehicles generally choose a charging system with multiple charging stages.