main content:

Rao Zhonghao et al. established a power battery cooling system as shown in Figure 1 to study the influence of PCM thermal conductivity on cylindrical battery systems. The single battery adopts a jacket structure, and the outer battery is covered with an annular steel shell. The annular cavity between the steel shell and the battery is filled with PCM, and the PCM used is paraffin. In order to overcome the low thermal conductivity of paraffin, a high thermal conductivity CF/PCM composite PCM was prepared with paraffin as the base material and copper foam (CF) as the skeleton material to enhance the heat transfer in the heat transfer medium. The battery module is composed of several single cells in series and parallel. The battery module contains 24 single cells. In order to avoid the local temperature in the middle part of the battery module being too high, the batteries are arranged in a crossed arrangement of positive and negative electrodes. The single battery is a 42110 type lithium iron phosphate (LiFePO4) power battery with a nominal capacity of 10A·h, a battery module voltage of 38V (12S×2P:S, Series; P, Parallel), and a capacity of 20A·h. The CF/PCM composite PCM fills the voids between the cells in the module. The melting point of the base paraffin wax has three different specifications: 37℃, 4℃, and 44℃. The latent heat of phase transition of the paraffin wax is ≥180kJ·kg-1·℃-1, and the thermal conductivity is about 0.2W·m-1·K-1. The skeleton material foam copper was purchased from Changsha Liyuan New Material Co., Ltd. The main parameters of the foam copper: the number of pores per inch (PPI) is about 20, and the density is about 0.4g·cm-3.

Figure 1 - Schematic diagram of a cylindrical power battery system model based on PCM heat dissipation

1. Thermal property test of battery

Through the study of the PCM-based cooling system shown in Figure 1, it is found that when the thermocouple used in the temperature measurement process is in contact with the battery surface, the measured temperature is mainly the temperature of the battery surface, and at the contact surface between the PCM and the battery, due to the complexity of the interface, there is a certain error between the measured temperature and the real value of the material on both sides of the interface. In order to quantitatively study the variation law and influencing factors of the internal temperature of the battery, the method of numerical simulation can be used to establish a corresponding model and conduct corresponding analysis. The thermophysical parameters of the battery (such as specific heat and thermal conductivity) are the key to accurately reflect the internal temperature change of the battery. A Hot Disk tester was used to test the thermal conductivity of the battery, and an EVARC acceleration calorimeter was used to test the specific heat of the battery (cell state of charge: 50% SOC). The thermal conductivity of the lithium iron phosphate single cell (the positive electrode material is lithium iron phosphate and the negative electrode material is graphite) measured at room temperature is about (3±0.05) W·m-1·K-1. Finally, the specific heat of the battery at different temperatures is obtained through simulation, as shown in Figure 2. It can be seen from the figure that as the temperature increases, the specific heat of the battery has a small fluctuation range, and the specific heat of the battery is assumed to be a fixed value at each temperature in the calculation. The average value of the specific heat in the temperature range shown in the figure is 1.1084 J·g-1·K-1.

Figure 2 - Battery specific heat measurement

2. Single battery thermal management system model

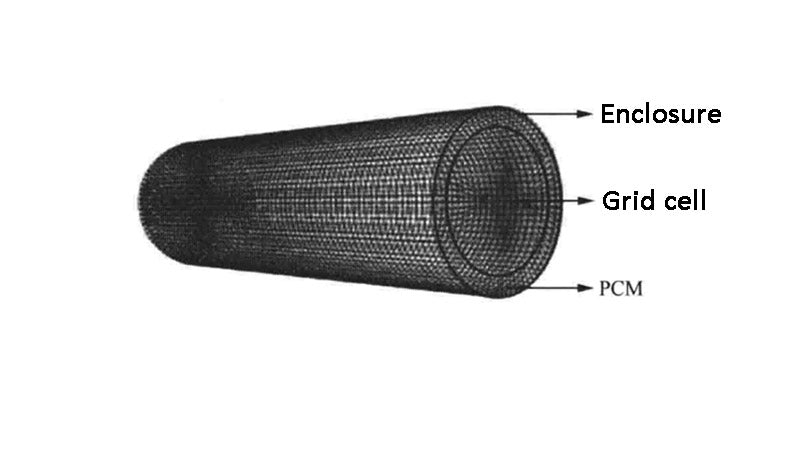

The heat generation and heat transfer characteristics of cylindrical batteries have been studied by numerical simulation methods, and there have been certain development in recent years. Al-Hallaj and Selman established a one-dimensional model of Li-ion battery based on the lumped parameter method, and studied the relationship between battery temperature and battery size under different discharge currents. Khateebl et al. designed a battery pack (3S×6P) consisting of 18 18650 cells with a capacity of 2A·h, and a simple two-dimensional unsteady heat transfer model is established, and the temperature profile of the battery pack when the PCM is paraffin (phase transition temperature is 40~44℃, solid thermal conductivity is 0.21W·m-1·K-1, liquid thermal conductivity is 0.29W·m-1·K-1) is given. Mills and A-Hallaj are based on the same size battery, established a model consisting of 6 batteries (1S×6P), using paraffin/expanded graphite as PCM, and studied the battery temperature change when the thermal conductivity of PCM was 16.6W·m-1·K-1. Subsequently, Khateeb et al. improved the model of the battery pack (3S×6P), using paraffin wax and foamed aluminum as PCM, and mainly analyzed the periodic change of battery temperature during 1C cyclic discharge. Sabbah et al. established a three-dimensional model of the battery pack (4S5P), selecting a PCM with a thermal conductivity of 16.6W·m-1·K-1 and a melting point of 52~55℃, compared the thermal management effects of air cooling and PCM cooling at ambient temperatures of 25℃ and 45℃; Kiziel et al. improved the model, and further gave the battery temperature change profile at different discharge times. At present, these studies are mainly based on the experimental results, through numerical simulation, to study the change of battery temperature under the assumed thermal conductivity or phase transition temperature of a certain PCM, and to verify the effectiveness of PCM for battery thermal management. In order to further study the influence of PCM thermal conductivity on the temperature rise and temperature distribution of the battery, a thermal management system model of a single battery as shown in Figure 3 was established.

Figure 3 - Single battery thermal management system model and grid

In the single battery thermal management system model, the battery is located in the middle, and a layer of PCM is wrapped outside. In order to improve the calculation accuracy, a grid similar to a copper coin as shown in Figure 3 is used in the radial direction of the battery, and the central part is encrypted; the PCM part uses a hexahedral mesh, and the meshing is completed in Gambit software.

According to the model basis of Kizilel et al., in order to simplify the calculation, the following assumptions are put forward for the single battery thermal management system model:

(1) During the solid-liquid phase transition of PCM, the volume change caused by the phase transition can be ignored, and the phase transition temperature is a fixed value rather than a certain range;

(2) The specific heat and thermal conductivity of the battery and PCM do not change with the change of temperature and spatial position;

(3) The complex chemical reaction inside the battery discharge process is not considered. The geometric dimensions of the thermal management system model of the single battery and the main thermal parameters of the battery and PCM are shown in Table 1.

Table 1 - Model geometry and thermophysical parameters

3. Relationship between PCM thermal conductivity and battery temperature change

In order to study the relationship between PCM thermal conductivity and battery temperature change, Rao et al. based on the calculation basis of the 42110 lithium iron phosphate single battery with a rated capacity of 10A·h discharged at a constant current of 5C for 12min, and studied the relationship between the maximum temperature inside the battery and time. In the experiment, PCM was not used for wrapping, and the heat dissipation only relied on the natural convection between the battery casing and the air. When the single battery is discharged at 5C to 720s, the maximum temperature inside the battery is 351.37K (78.22℃). When PCM is used to dissipate heat, as the thermal conductivity of PCM changes from 0.2W·m-1·K-1 to 3.0W·m-1·K-1, the change of the highest temperature inside the battery is shown in Figure 4.

Figure 4 - The maximum temperature change of the battery under different PCM thermal conductivity

Through research, it is found that when the thermal conductivity of PCM is 0.2W·m-1·K-1, 0.4W·m-1·K-1, 0.8W·m-1·K-1, 1.6W·m-1·K-1, respectively, the corresponding maximum internal temperatures of the battery are 329.16K (56.01°C), 326.20K (53.05°C), 323.75K (50.6°C), 321.89K (48.74°C) and 320.80K (47.65°C), respectively. This is because the greater the thermal conductivity of the PCM, the more timely the heat can be transferred from the contact end between the PCM and the battery to the contact end between the PCM and the external environment, avoiding the increase of the thermal resistance of the battery heat transfer to the outside due to the low thermal conductivity after the PCM at the contact end of the battery is melted, and reduce the temperature difference between the inside and the surface of the battery. At the same time, it is not difficult to see that with the increase of the thermal conductivity of PCM, the maximum temperature inside the battery shows a downward trend, and after the thermal conductivity of PCM increases to a certain value, the maximum temperature inside the battery has a gentle downward trend. That is to say, after the amount of PCM is limited, its thermal conductivity is not as large as possible. In addition, in order to improve the thermal conductivity of PCM, the method of filling high thermal conductivity is generally used. While under the same volume, the larger the thermal conductivity, the smaller the latent heat of PCM. The change in the amount of PCM caused by this will further affect the temperature distribution of the battery pack, and even affect the volume and economy of the system. Therefore, proper PCM thermal conductivity is one of the key parameters for designing battery thermal management systems.

In addition, when a PCM with a thermal conductivity of 0.2W·m-1·K-1 was selected for research alone, it was found that the temperature distribution of the single battery module at different discharge times is shown in Figure 5. When the discharge time is t=120s, since the thermal conductivity of the PCM is lower than that of the battery, the temperature of the interface between the PCM and the battery is significantly higher than the temperature of the interface between the PCM and the external environment; as the discharge time continues to increase, at t=240s, as the battery temperature increases, the temperature of the PCM in contact with the battery, that is, the temperature of the inner PCM is close to the melting point; when discharged to t=360s, the inner PCM has begun to melt, and as the battery temperature continues to rise, the temperature of the inner PCM has exceeded the melting point; from t=480s to the end of discharge, the battery temperature continued to rise, but the PCM continued to absorb heat mainly in the form of latent heat, and the temperature difference between the inner and outer PCM gradually decreased. It can be seen from the radial distribution of the temperature of the battery module that when the thermal conductivity of the PCM wrapped around the battery is much smaller than that of the battery itself, although PCM can rely on latent heat to reduce the maximum temperature inside the battery, it is prone to the situation that the inner PCM is completely melted and the outer PCM has not yet melted.

Figure 5 - Radial distribution of temperature in the battery module at different times

As shown in Figure 6, it is the distribution of the radial temperature of the single battery module obtained by the above method when the thermal conductivity of the PCM increases from 0.2W·m-1·K-1 to 3.0W·m-1·K-1; and when the thermal conductivity of PCM is 0.2W·m-1·K-1, the temperature changes with discharge time at different radial distances (R) from the center of the battery.

Figure 6 - Radial temperature change of battery module with different thermal conductivity

It is not difficult to see that as the thermal conductivity of the PCM increases, the temperature difference between the inside and outside of the PCM decreases. When the thermal conductivity of PCM increases to the same as the thermal conductivity of the battery itself, from the temperature distribution between R=0 and R=17, it can be seen that the temperature gradient at the contact interface between the battery and the PCM also decreases accordingly, and the temperature distribution curve is significantly smoother. The temperature difference between the center of the battery (R=0) and the end of the battery near the outer surface (R=20) increases with the discharge time. When the PCM begins to melt, the temperature difference increases rapidly, but due to the latent heat of phase transition, the temperature difference does not continue to increase significantly as the battery continues to generate heat. The existence of the temperature difference between the center of the battery and the outer surface is mainly due to the thermal resistance of the battery itself, and is also affected by the thermal conductivity of the PCM. Therefore, when choosing a suitable PCM melting point, the existence of the thermal resistance of the battery itself must be considered, and the design of the battery thermal management system needs to take into account the combined influence of the thermal properties of the PCM and the thermal properties of the battery.