Main content:

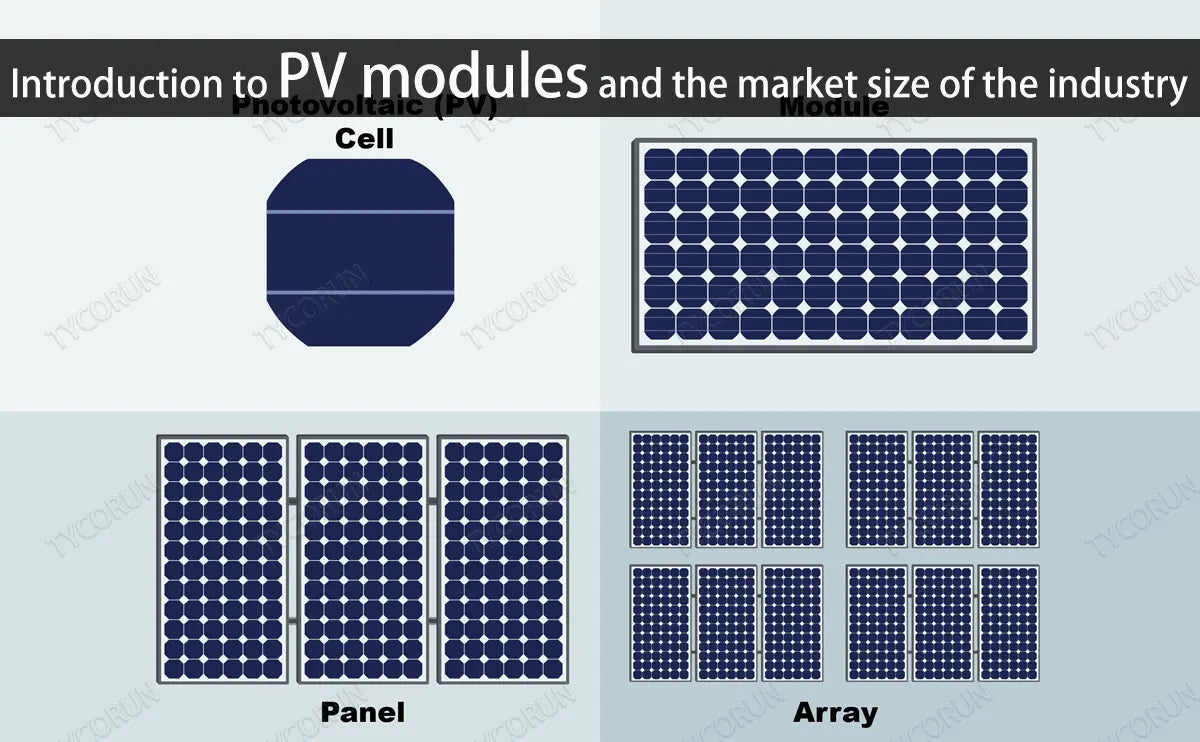

The core components of photovoltaic modules, photovoltaic cells, have limited power generation per piece, and need to be connected in series and packaged as modules before they can be used as a power source.

It is composed of a certain number of photovoltaic cells connected in parallel through wire series and packaged, mainly including core components such as cells (generally 60 or 72 cells), interconnection strips, busbars, photovoltaic glass, adhesive films, backsheets, aluminum frames, junction boxes, etc.

1. Classification of solar modules

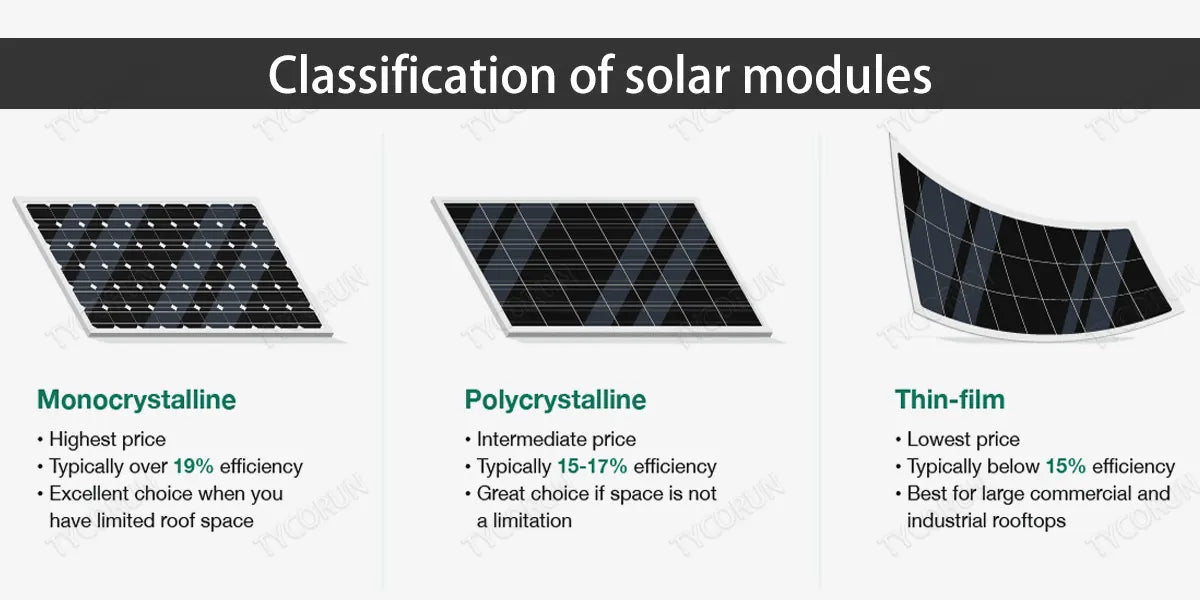

- Crystalline silicon modules and thin film modules

Photovoltaic modules are divided into crystalline silicon modules and thin film modules. Among them, crystalline silicon modules account for 90%–95% of the total photovoltaic modules due to the high power generation power of single modules, and thin film modules only account for about 5%–10%.

- Double-glazed and single glazed modules

Crystalline silicon photovoltaic module can be divided into double glass modules and single glass modules according to the back material. Most of the backsheet materials of single glass modules are opaque composite materials (TPT, TPE, etc.), and single glass modules are still mainstream, with the market share of single glass modules in 2020 being about 70%-75% and double glass modules accounting for about 25%-30%.

The double-glass module uses glass instead of the composite backplate of the single-glass module, and the double-sided glass package is glass-encapsulated. Compared with single-glass modules, double-glass modules have a longer life cycle, stronger weather resistance and corrosion resistance.

And lower attenuation than ordinary modules, higher power generation efficiency, both front and back have power generation capacity, and the back side can accept the reflected light and scattered light of the surrounding environment to convert into electrical energy, and the bifacial modules can increase the power generation by 10%–30% according to different ground environments.

2. The modules are located in the middle of the industrial chain

Driven by industrial policy support and global market demand, China's photovoltaic technology continues to progress. It has formed a complete industrial chain from silicon materials to the construction and operation of photovoltaic systems, and has a high industrial scale advantage in the world.

The upstream of the photovoltaic industry includes the smelting, ingot/rod casting, slicing and other links of monocrystalline polysilicon, the midstream includes the production of photovoltaic cells, the packaging of power generation modules, etc., and the downstream includes the integration and operation of photovoltaic power station systems.

The photovoltaic industry has been in a state of rapid development in recent years, and at the same time, the manufacturing of photovoltaic equipment and components is also booming.

At present, photovoltaic power generation has a cost advantage compared to traditional fossil power generation and has entered the era of parity. With the advantages of cost and carbon reduction, photovoltaic power generation has become the main force of new power generation in the world.

3. Photovoltaic cells - mainly crystalline silicon cells

Photovoltaic cells are the basic core components of photovoltaic power generation systems, which are divided into two categories: crystalline silicon cells and thin film cells according to the differences in materials used, with the former occupying the main market share, and the latter benefiting from the development of photovoltaic buildings, and the penetration rate is expected to increase.

After decades of development, crystalline silicon solar cells have a relatively mature technical system. Photoelectric conversion efficiency continues to improve, and industrial scale expands rapidly, and marginal manufacturing costs are significantly reduced.

In the current photovoltaic industry, crystalline silicon cells occupy more than 95% of the photovoltaic cell(12v 100ah lithium ion batteries) market by relying on the economic cost advantages and high conversion efficiency brought by the scale effect. The monocrystalline field is divided into two technical routes: P-type and N-type.

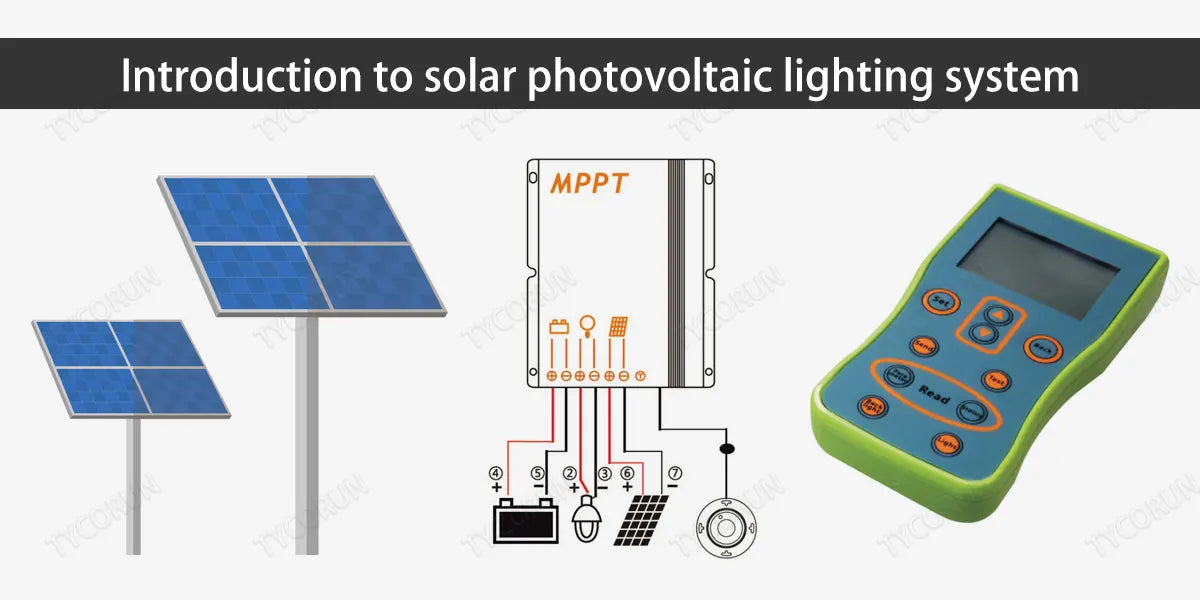

4. Introduction to solar photovoltaic lighting system

According to the different needs of users and the current situation of the site, a variety of design schemes can be provided. Let users have enough choice, completely tailored to the needs of users, so that users are satisfied. The solar lighting system uses sunlight as the energy source, which can be charged during the day and used at night, without external power supply, which is safe, reliable, green and energy-saving.

The process of charging, turning on and off the lights is intelligently controlled by a microcomputer. The lights are automatically turned on when it is dark, and the lights are automatically turned off at dawn, without manual operation, and have a long service life, which is an ideal lighting tool in the modern living environment. The solar lighting system is a fully automatic working system, as long as the working mode of the system is set, it can work automatically.

The control mode is generally divided into light control mode and timing control mode, and the working mode of light control or light control and timing combination is generally adopted. When the light intensity is lower than the design value, the controller starts the light to light up, and starts the timer at the same time, and the light source turns off when the timer reaches the set time.

5. Solar photovoltaic lighting system features

Clean and environmentally friendly: The solar lighting system uses clean and renewable energy, which does not pollute the environment.

Long life: Solar modules have a service life of up to 25 years, and can still be used after 25 years, but the conversion efficiency will be reduced.

High efficiency: Solar cell power point tracking technology can maximize the effective power through the optimal combination of current and voltage.

High brightness: The use of high-efficiency solar cell modules as the power generation components of the lamp combined with the optimal angle design of the solar panels provides sufficient energy for the LED light source, and truly realizes the brightness of the night as day.

Convenient management: the whole system is fully automatic and unattended by microcomputer control.

Safe and reliable: The charging and discharging process of the solar lighting system is carried out in a low voltage state, which is not harmful to the human body.

Fast construction: Each solar lighting system is an independent lighting unit, charging, discharging, lighting, and control are all completed independently, no need to dig trenches, no need to bury pipes, no wiring, instant installation, and instant use.

6. Conclusion

Photovoltaic modules are based on cellular integration, packaging, and internal connectivity. They can provide independent DC output, making them the smallest and most inseparable photovoltaic cell(12 volt 200ah lithium battery) combination device.

As the smallest effective power generation unit, it performs the photoelectric conversion function in the photovoltaic power station, which is the core part of the photovoltaic power generation system.

Related articles: Maximum Power Point Tracking, solar battery price, home photovoltaic energy storage