Main content:

In recent years, with the growing demand for wearable and flexible electronic products, flexible and high energy density energy storage devices have developed rapidly.

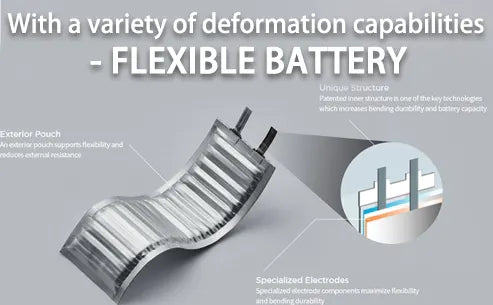

The flexible battery has high energy density and stable electrochemical performance in various energy storage systems, and is considered the most promising battery technology for wearable electronics. However, most flexible battery today is lithium-ion batteries. It consists only of a complete anode, separator, cathode stack, resulting in overall performance not as good as a rigid battery.

1. The mechanism of flexible battery

The key to the good flexibility of human joints such as knuckles is to help the smooth rotation of joints due to the special structure of their joint surfaces, so as to achieve the flexibility of our fingers. Based on this inspiration, flexible lithium-ion batteries appeared.

First, the stacks of graphite anodes, separators, lithium cobalt oxide (LCO) cathodes are divided into interconnected segments, each folded in half. Each folded segment can then be rolled into a thick stack with a prismatic shape. At the junction, it consists of two thick rigid stacks and a thin flexible part.

- The thick lamination helps cushion the stress caused by deformation and provides the main capacity for the flexible battery.

- The thin flexible section connects thick rigid stacks to each other and gives the battery excellent flexibility.

In addition to winding in a prismatic shape, it is also possible to change the winding method. For flexible battery with prismatic energy storage units, compared with the traditional flexible battery structure, it has obvious advantages in improving energy density, and its relative energy density can easily exceed 90%.

For batteries with cylindrical energy storage units, they can be bent anywhere along the long side of the battery and can withstand more complex deformations. In addition, the length of the connecting portion between the two cylindrical elements allows it to be stretched.

By filling it with an elastic polymer material, flexible cells with cylindrical cells can be made into flexible and stretchable lifepo4 battery. For batteries with other shaped cells, it can be designed according to the actual requirements of the application scenario.

2. Advantages of flexible battery

Compared to conventional batteries, flexible lithium metal batteries should be able to:

- Withstands bending, folding and stretching

- Wearable, waterproof and flame retardant

- Self-healing performance

- Impact damage resistance

Therefore, each component of a flexible lithium metal battery, including electrodes, electrolytes, current collectors, etc., should be transformed from traditional rigid or brittle substances into a ductile matrix. Generally, flexible battery can only achieve one deformation at a time, that is, bending deformation or twisting deformation.

For batteries with cylindrical cells, the length of the connecting part is sufficient, which allows the battery to achieve complex bending and torsional deformation. Winding is considered a higher standard for evaluating flexibility. Thanks to the round shape, batteries with cylindrical units offer greater flexibility.

3. The composition of the flexible battery

In addition, some battery cells should consider mechanical stability, hydrophobicity, and flame retardancy, and each component should be stably connected in its original order to prevent battery failure. It mainly includes the design of flexible anode, electrolyte, cathode material and its interlayer.

● Flexible anode

Pure lithium metal is soft (0.6 on the Mohs scale), plasticity (about 50–70% ductility) cannot be restored, and cracks occur during repeated bending, folding, or stretching. Low mechanical flexibility, high reactivity and dendrite growth at lithium metal cracks hinder the practical application of flexible lithium metal batteries.

● Non-fluid electrolytes

The current demand for lithium metal batteries that are highly safe, lightweight, wear-resistant, and environmentally friendly has led to the development of new structures. Batteries with conventional liquid electrolytes are at risk of leakage, and electrode materials are prone to corrosion, making the design and assembly of wearable electronic devices difficult.

Compared to pure liquid electrolytes, solid electrolytes (SSEs), gel polymer electrolytes (GPEs), and quasi-solid electrolytes (QSEs) are non-fluid forms and may be collectively referred to as non-fluid electrolytes.

Non-liquid electrolytes are more reliable at inhibiting lithium dendrites, improving battery safety and deformation. Wherein the solid electrolyte comprises an inorganic solid electrolyte, a solid polymer electrolyte and an inorganic-polymer composite solid electrolyte.

However, the lack of ionic conductivity and electrochemical window is still an obstacle to further application. The top 5 battery electrolyte companies are try to develop new electrolyte materials with high ionic conductivity, chemical inertness, mechanical stability and flexibility. Flexible battery with this novel structure have excellent flexibility and mechanical resistance.

4. Electrochemical properties of flexible battery

● Prismatic unit

Batteries with prismatic cells are flat and have little capacity decay. Therefore, this flexible battery with novel structure has high adaptability to various deformations. Since most flexible electronic devices are accompanied by dynamic deformation during use, matched flexible battery can undergo tens of thousands of dynamic cycles throughout use.

Therefore, electrochemical performance and durability are basic requirements, which is also a major challenge for flexible battery in practical applications. Due to the novel design, the battery capacity does not decay significantly.

● Cylindrical unit

Due to the inherent properties of the ring, flexible battery with cylindrical units can withstand more extreme and complex deformations. The electrochemical performance of this flexible battery has hardly changed. Again, there is no significant reduction in capacity.

The corresponding charging and discharging platforms with different cycles are almost unchanged, indicating the excellent stability and mechanical resistance of this flexible battery.

Since flexible equipment usually does not produce a single deformation during use, the stability of the battery under dynamic composite deformation is also quite important. In addition, this novel structure allows the metal current collector to always be in the range of elastic deformation, making the flexible battery have excellent mechanical durability and electrochemical stability.

5. Application of flexible battery

● Current existing problems

The theoretical energy density of lithium metal batteries is higher than that of lithium-ion batteries, lead-acid batteries, nickel-metal hydride batteries, zinc-manganese batteries and other energy storage devices. Although the popularity of research has increased in recent years, the top 10 lithium ion battery anode material companies are still in their infancy of flexible battery development.

Indicators for measuring flexible lithium metal batteries mainly include real energy density and flexibility indicators, taking into account practical applications. Among them, the following are crucial:

- Development of anodes with excellent electrochemical performance.

- Development of electrolyte materials with new structures and high ionic conductivity.

- Improve flexibility and elemental utilization of high-capacity cathode materials.

- Reasonable battery configuration design.

- Integrate safety features such as waterproof and fire resistance, self-healing, and impact resistance to meet wear requirements.

● Wearables

Because batteries with different cell shapes can provide different flexibility. Batteries with prismatic units power headphones and longer watches. Batteries with cylindrical cells can be used in devices with higher flexibility requirements due to their stretchable properties. The battery with a triangular prism unit is easy to carry because it can be wound into a rigid columnar battery, which can be used as a mobile phone charger to charge the flashlight.

6. Conclusion

Although some structures are designed for flexible lithium-ion batteries and provide better variability capabilities. However, these flexible battery is still difficult to cope with extreme deformations including folding, stretchable, winding and composite deformation.

Therefore, flexible lithium-ion batteries that can simultaneously adapt to multiple deformations, have high mechanical resistance and high energy density remain a huge challenge. With the urgent need for high energy density in various wearable electronics, mobile terminals and electric vehicles, and the need for lightweight, portability and flexibility in modern energy storage devices. The new generation of flexible battery has been extensively studied.

Related articles: lithium metal battery, prismatic cell, lithium ion battery electrolyte