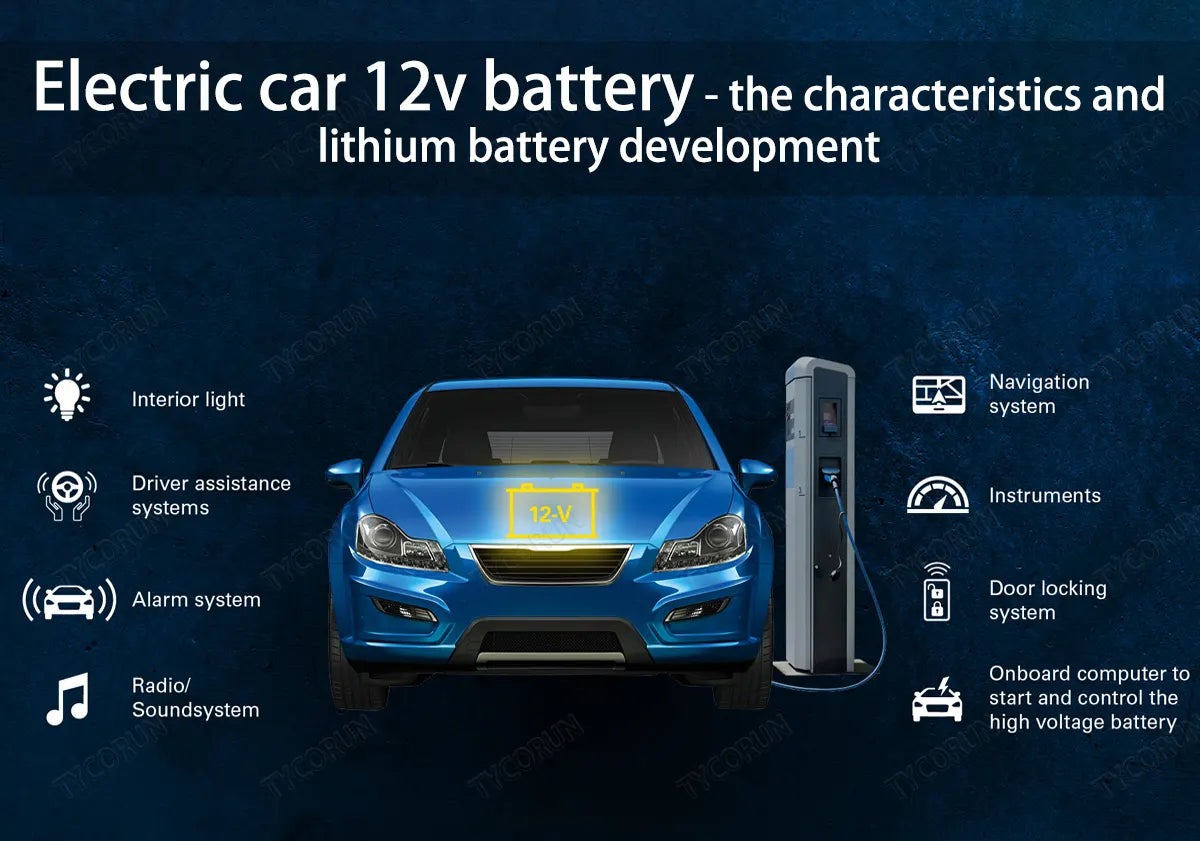

Electric vehicles have two completely different power systems. The main driving system is high voltage, usually 400V-800V, which is the power source of the high-torque motors on the wheels. The other is the 12V power system.

Most electronic equipment in electric vehicles, including infotainment systems, power door locks, power windows, HVAC fans, and safety systems (airbags and ADAS technology), use no more than 12V. This article will give a detailed introduction to the electric car 12v battery.

Main content:

- What is electric car 12v battery

- Working mode of electric car 12v battery

- Application scenarios of electric car 12v battery

- Functions of electric car 12v battery

- Lithium-ionization direction of electric car 12v battery

- Lithium-ionization product design

- Electric car 12v battery lead acid vs lithium iron

- Market size of electric car 12v battery

- Technical requirements for electric car 12v lithium battery

- Industry layout of electric car 12v lithium battery

1. What is electric car 12v battery

The electric car 12v battery plays a key role in automotive applications as a backup power supply, starting battery and output stabilizer. The traditional 12v battery is a lead-acid battery, which is divided into three categories: SLI, EFB and AGM according to the application level and direction, as shown in the table below:

|

Category |

SLI |

EFB |

AGM |

|

Name |

Starting-lighting-ignition battery |

Enhanced flooded battery |

Absorbent glass mat battery |

|

Function |

12V power supply |

12V power supply and start and stop |

|

|

Installed models |

Models without start/stop requirements |

Mainly installed on Japanese models |

Mainly installed on European and American models |

|

Installation location |

/ |

Engine compartment |

Normal temperature environment: under the seat or in the trunk |

|

Performance characteristics |

Meet the needs of vehicle electrical equipment |

High temperature resistance, meet the requirements of start and stop system, high cost performance. |

Not resistant to high temperature, excellent start and stop ability, the most advanced battery technology at present |

|

Charging ability |

⭐ |

⭐⭐ |

⭐⭐⭐ |

|

Life |

⭐ |

⭐⭐ |

⭐⭐⭐ |

|

Price |

⭐ |

⭐⭐ |

⭐⭐⭐ |

|

Applicable models |

Non-start-stop ordinary models |

Non-start-stop ordinary models and entry-level start-stop systems |

Non-start-stop ordinary models and all start-stop models |

For more information, you can click to check the knowledge of agm vs lead acid.

The 12V battery itself has a relatively low voltage, so when used in some scenarios, it generally requires a large current output to achieve high power. Usually 12V batteries pay more attention to battery capacity. Battery capacity can represent both storage capacity and maximum output power, followed by charging capacity, and pulse ability-starting ability based on capacity.

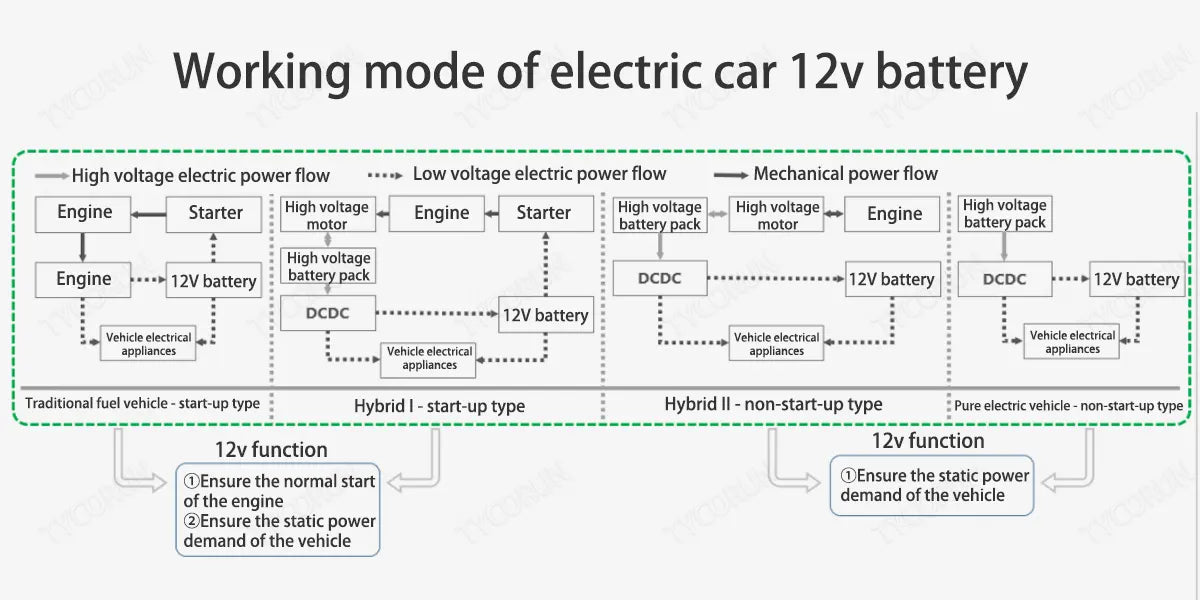

2. Working mode of electric car 12v battery

The main function of the electric car 12v battery is to supply energy to electrical devices and start the engine. Secondly, the auxiliary power supply function requires pulse charging ability. The specific working mode is as the figure below:

3. Application scenarios of electric car 12v battery

|

Items |

ICE |

HEV |

PHEV |

EV |

||

|

Light mix |

Strong mix |

|||||

|

Power source |

Gasoline |

Gasoline+electricity |

Electricity |

|||

|

Power supply voltage |

12V |

48V |

≥100V |

|||

|

Output power |

2~6kW |

5~20kW |

≥30kW |

|||

|

Low voltage |

12V power supply |

12V lead-acid/12V LiB |

||||

|

Engine starting |

12V lead-acid/12V LiB |

/ |

||||

|

Auxiliary power supply |

/ |

LiB |

Ni-MH/LiB |

LiB |

||

|

Backup power supply |

12V lead-acid/12V LiB |

|||||

|

High voltage |

Power supply |

/ |

Ni-MH/LiB |

LiB |

||

4. Functions of electric car 12v battery

Power supply range of electric car 12v battery:

- Electrical appliances: Electric car 12v battery supplies power to vehicle electrical appliances, such as: car lights, speakers, screens, etc.

- Engine starting: Used for car starting power supply.

- Auxiliary power supply: When the generator power is insufficient, the 12V power supply appropriately supplements the power; when the generator power is too high, the 12V power supply stores energy.

- Backup power supply: When the on-board 12V fails, the backup power supply is temporarily used to start the vehicle (non-on-board power supply).

5. Lithium-ionization direction of electric car 12v battery

- Cost of use (product price/service life): Among the three types of electric car 12v lithium battery, EFB and AGM are relatively expensive and have the prospect of being lithium-ionized, while the cost of SLI lithium-ionization is too high.

- Function: The function of on-board 12V power supply mainly focuses on power supply and engine starting.

- Power supply: The power of the electric car 12v battery is related to the energy consumption of the electrical equipment under static conditions and the prescribed static power consumption time, and is used in the traditional automobile field and the new energy automobile field.

- Engine starting: The 12V power supply is related to matching engine starting and is mainly used in traditional automotive fields.

- Size: The size of the electric car is related to the application field.

- 12v battery for passenger vehicle models: The size is mainly concentrated at 175mm*190mm (width*height), the length changes with the capacity, and is used by current new energy vehicles.

- 12V battery for commercial vehicle models: Commercial vehicles have advantages at the installation space and high engine power requirements, and their sizes are relatively variable.

6. Lithium-ionization product design

Replacing 12V lead-acid battery:

The size should be consistent with the lead-acid battery, and the performance should reach the power performance of the lead-acid battery. The high-temperature applicability and reduced maintenance cost are the main advantages of the 12v lithium ion battery pack.

New 12V system for new energy vehicle:

Based on the functions mainly focusing on 12V power supply, the high-voltage system automatically recharging the 12V system under static conditions, and the high energy density of the lithium battery itself, the system capacity, power performance and power supply size can be redesigned.

7. Electric car 12v battery lead acid vs lithium iron

|

Performance |

Lithium iron phosphate battery |

Lead-acid battery |

|

Cycle life |

2500~4000 cls |

300~500 cls |

|

High and low temperature resistance |

-20~50℃ |

-5~30℃ |

|

Start-stop warranty |

About 10 years |

≤2 years |

|

Depth of discharge |

80% |

50% |

|

Power performance |

Stable voltage output/low weight/strong power |

high voltage in the first half, low voltage in the second half: power weakened at low voltage |

|

Memory effect |

No memory effect |

With memory effect |

|

Weight comparison of the same specifications |

The lead-acid system is 3 to 4 times heavier than the lithium iron phosphate system, and the lithium iron phosphate system is 1.5 to 3 times more expensive than the lead-acid system. |

|

Disadvantages of lead-acid batteries

- Lifespan: The lifespan of lead-acid batteries is not long, and the in-depth development of intelligent 12V vehicle systems has increased the power consumption, further shortening their service life, and the service life is difficult to predict.

- Environmental concerns: Lead-acid batteries are not environmentally friendly.

The pain points of lithium-ionization

The large-scale application of lithium batteries in the power field has promoted the accelerated iteration of battery technology, and the production cost has continued to decline, providing the possibility to start the lithium electrification of power sources and its large-scale application. Lithium batteries can be used as emergency power when the energy supply of the power system fails.

There are many benefits of using lithium batteries in cars, but lithium electrification still has the following pain points:

- Market process: Mainstream electric car companies and traditional car companies still choose lead-acid batteries, and the overall lithium-ionization of electric car 12v battery is progressing slowly.

- Implementation policy: Lack of targeted policies for electric car 12v battery lithium-ionization.

- High technical threshold: Low-voltage high-rate batteries require normal operation at -30℃ and meet the high current and high cycle durability required for ICE startup. The technical barriers are very high.

- Cost barrier: The price of lithium battery version of electric car 12v battery is generally higher than 1,100RMB, which is about 1.5-3 times the price of lead-acid, which is also an important factor hindering the conversion from lead to lithium.

There are few battery manufacturers and few battery products that meet the requirements. At present, only a few car companies such as Tesla, Porsche, BYD, Hyundai, and Kia have started lithium-ionization, and none of them have been promoted on a large scale.

8. Market size of electric car 12v battery

Traditional fuel vehicles

According to statistics, global car sales in March 2021 were 229 million vehicles. If all 12V starting power supplies are replaced by lithium batteries, the corresponding annual demand for lithium batteries will reach 68.7GWh (average power 300Wh/car).

New energy vehicles

According to predictions by relevant organizations, global electric vehicle sales will reach 15 million units in 2025. Global electric vehicle sales will reach 23 million units in 2030. If the 12V vehicle power supply uses LFP battery to replace lead-acid batteries, the installed battery capacity will be 100-500wh/car.

Calculated based on the battery capacity of 300wh/car, the proportion of LFP replacing lead-acid batteries in 2025 will be 10%, corresponding to the 12V system lithium battery demand of approximately is 0.45GWh. If the replacement ratio is 50% in 2030, the corresponding 12V system lithium battery demand will reach 3.45GWh.

|

Forecast of 12V market demand in the global new energy vehicle market |

||||

|

Year |

Global new energy vehicle market sales (10,000 units) |

12V lithium battery capacity (wh/vehicle) |

LFP replacing lead-acid ratio |

Annual demand for 12V lithium batteries (GWh) |

|

2025 |

1500 |

300 |

10% |

0.45 |

|

2030 |

2300 |

300 |

50% |

3.45 |

|

2030 |

2300 |

300 |

100% |

6.9 |

|

Note: 1. New energy vehicles include passenger cars and commercial vehicles. 2. The current battery power is concentrated at 100-500wh/car. The above data is calculated based on 300Wh. |

||||

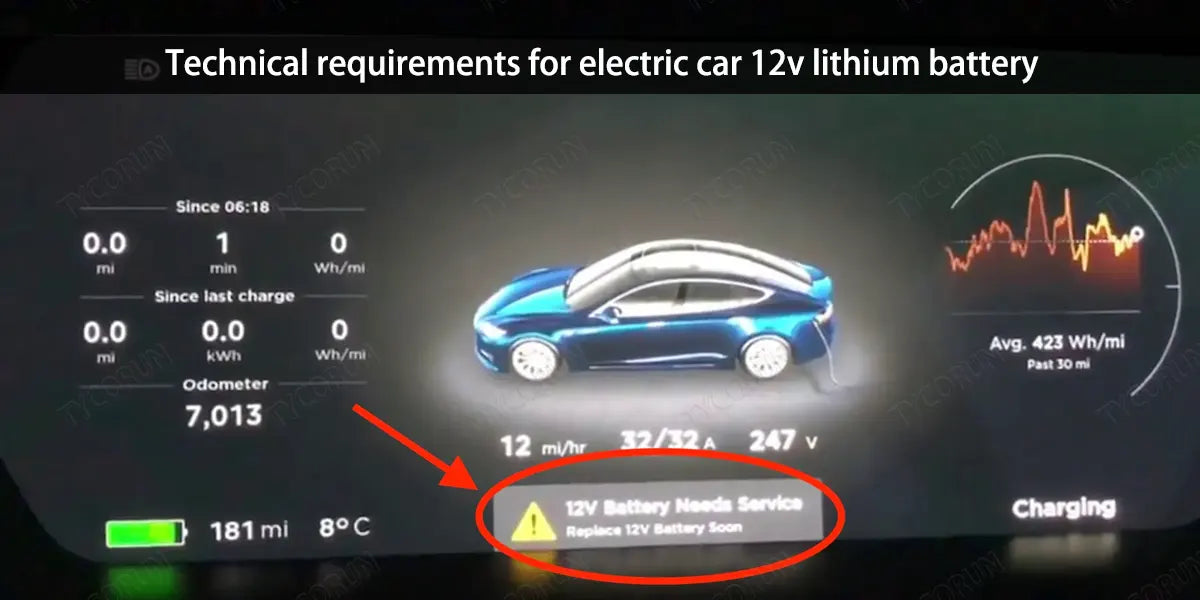

9. Technical requirements for electric car 12v lithium battery

- Charge and discharge rate: (pulse) charging 30C, discharging 40C

- Lifespan: In line with the high-voltage system of new energy vehicles, battery life is required to be ≥10 years and the number of starts and stops is ≥200,000 times

- High temperature performance: The 12V battery is installed in the engine compartment, and the internal temperature can reach above 80℃, so the maximum temperature that the 12V car battery can withstand is ≈80℃

- Consistency: Since electric car 12v lithium battery is discharged at a high rate, defects are infinitely magnified and will affect the overall performance, so the requirements for consistency are high and the terminal car battery voltage difference is required to be <50mV.

10. Industry layout of electric car 12v lithium battery

- CATL: Developed a 12v lithium battery auxiliary power supply that is 80% lighter and 60% smaller than traditional lead-acid batteries.

- EVE Energy: Jaguar Land Rover and Daimler have designated 12v projects. In February 2021, EVE Energy planed to invest 2.6 billion RMB each to build the "xHEV battery system project (Phase I)". The project content is 12V and 48V battery systems.

- Wanxiang A123: Wanxiang began to develop the first-generation 12v starter battery in 2011, mass-produced the second-generation Nano-LFP in 2013, and the third-generation was mass-produced in 2017. Currently, the focus of considering the fourth-generation 12v battery is how to make the cost lower.

- Camel Group: The 12v low-voltage lithium battery is in contact with a number of European and American high-end car companies and has passed technical review and business negotiations. Related products are as follows:

|

LFP |

CATL |

BYD |

BYD |

EVE |

Camel |

Camel |

A123 |

A123 |

|

Type |

Cylindrical |

Square |

Square |

Square |

Soft pack |

Soft pack |

Soft pack G2 |

Soft pack G3 |

|

System |

LFP/Gr |

LFP/Gr |

LFP/Gr |

LFP/Gr |

LFP/Gr |

LFP/Gr |

Nano-LFP/Gr |

Ultra-LFP/Gr |

|

Capacity |

20Ah |

20Ah |

10Ah |

22Ah |

20Ah |

30Ah |

20Ah |

20Ah |

|

Nominal voltage |

3.2V |

3.2V |

3.2V |

3.22V |

3.2V |

3.2V |

3.3V |

3.3V |

|

Dimension/mm |

46*145 |

/ |

/ |

17*148*128 |

/ |

/ |

?*161*227 |

14.2*150*144 |

|

Energy density |

121Wh/kg |

/ |

/ |

116Wh/kg |

/ |

/ |

/ |

125Wh/kg |

|

Lifespan |

>8000 cls 25℃@70% |

>3000 cls 25℃1C/1C @80% |

>3000 cls 25℃1C/1C @80% |

90000Ah(Disc.) |

(System 8 years) |

(System 8 years) |

/ |

/ |

|

Service temperature range |

-30~65℃ |

-29℃~ |

/ |

-40~60℃ |

/ |

/ |

/ |

/ |

|

Application field |

12V system |

12V system |

12V system |

12V system |

12V system |

12V system |

12V system |

12V system |

|

Development status |

/ |

2021.Q4 |

2021.Q4 |

/ |

2022.Q1 |

2023.Q1 |

2013.SOP |

2017.SOP |

Related posts: car battery recycling, lithium ion battery life, marine battery vs car battery